Performability Engineering

Introduction to Performability Engineering

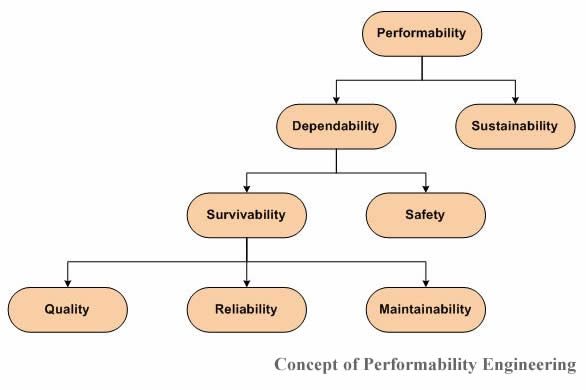

The concept of Performability Engineering as put forward by Professor KB Misra can be “defined as the entire engineering effort that goes into improving the performance of a system that not only ensures high quality, reliability, maintainability and safety but is also sustainable”¹. This was the bedrock concept that led him to start the International Journal of Performability Engineering (IJPE) in 2005 as well as author and edit several books, including The Handbook of Performability Engineering (ISBN: 978-1848001312), published by Springer-Verlag in 2008.

Prof. K. B. Misra was invited at the beginning of the 21st Century to contribute to Encyclopaedia of Life Support Systems (EOLSS) produced by United Nations Educational, Scientific & Cultural Education, and he contributed a chapter on Role of Performability Engineering in Sustainable Development to Principles of Sustainable Development Section Vol. II this Encyclopaedia Download Chapter Sample.

Imperatives of Performability Engineering

The phenomenal advances made during the last Century in information technology have generated high expectations for an unprecedented revolution in all scientific and technological fields in the 21st Century. Newer and smart materials along with composites and biodegradable materials that include high strength plastics, minimum waste or effluent-producing processes, material recycling, use of clean energy sources and ever-decreasing levels of energy requirement, nano-materials are some of the strategies that will govern the design of all future products in the 21st Century. Key areas like genetic engineering, biotechnology, nanotechnology hold the key to developing sustainable products, systems and services. In fact all future technological pathways would help minimize if not reverse the damage that has already been done to the earth’s environment by the last industrial revolution.

As of now, the performance of products, systems or services is judged in terms of dependability, which aggregates attributes, like quality, reliability, maintainability, safety etc., not overlooking the cost of achieving these attributes. But in fact these attributes are very much influenced by the design, raw material, fabrication, techniques and manufacturing processes and their control and finally by the usage.

With the world resources on decline and the human population on the rise, the cost of raw materials and resources is likely to escalate in a spiral fashion in near future. Past few decades have already witnessed this phenomenon. To keep pace with rising population, the increased volume of production is likely to affect the world environmental health further unless pollution prevention measures are strictly pursued. Therefore, the control of effluents and waste management along with minimization of energy requirements should become even more important considerations in designing products and their manufacturing processes. Moreover, the internalization of hidden costs of environment preservation will have to be accounted for, sooner or later, in order to be able to produce sustainable products in the long run. Therefore, it is time we start taking a holistic view of the entire life cycle of activities along with associated cost of environmental preservation at each stage of product manufacturing and use while maximizing performance.

The conventional perspective of dependability ignores the environmental impact considerations that accompany the development of products, systems and services. However, any industrial activity in creating a product, system or service is not free from the environmental impacts that follow at each phase of development.

The concept of Performability allows us to take holistic view of entire life cycle activities connected with the design, manufacture, use and disposal in relation to performance, environmental and economical considerations. In other words, performability is an aggregate attribute that reflects an entire effort of a system engineer in achieving dependability and sustainability.

Therefore, our concern in performability engineering is not limited to designing products, systems and services for performance in conventional sense but also consider optimizing the processes that create them. It is not difficult to visualize that by employing the strategy of dematerialization, minimum energy and minimum waste while maximizing the yield and developing economically viable and safe processes (clean production and clean technologies), we will create minimal adverse effect on the environment during production to disposal at the end of the life. This is basically the aim of performability engineering.

At present, researchers in the areas of quality, reliability, maintainability and availability and safety are hardly concerned with sustainability aspects of product design (implying dematerialization, requiring minimum energy, generating minimum wastes and using pollution prevention strategies) and are working in isolation. Similarly, those working in sustainability do not concern themselves with dependability considerations. Therefore, it is true that the existing journals on the subject of quality, reliability, maintainability and safety hardly ever deliberate the issues related to product or system sustainability, nor do the journals on sustainability and related areas ever touch upon problems of quality, reliability or safety. A truly optimal design must balance out all these conflicting conditions imposed upon the product or system development while resorting to clean manufacturing processes. We need to address the inherent complex problems of this task from the perspectives of performance, environment and economics all taken together as the sustainable products shall have to be produced in a competitive world market.

The concept of Performability Engineering aims to bridge this gap of information between the diverse groups of researchers so that the challenges of the designers, manufacturers and users of 21st Century products and systems can be met effectively. Nanotechnology, Biotechnology and other clean technologies and processes and strategies of recycle and reuse and environmental directives are likely to dictate and revolutionize the way products and systems will be designed, manufactured and used in the 21st Century. This interaction, if encouraged, is likely to usher in a new technological revolution, whose doorstep we find ourselves today.

[1] Misra KB (Ed) The Handbook of Performability Engineering. Springer-Verlag, 2008: 11